3D Printing Production: Companies are using 3D printing in unique means to enhance as well as improve production.

Lear more on What is 3D Printer and 3D Printing?

|

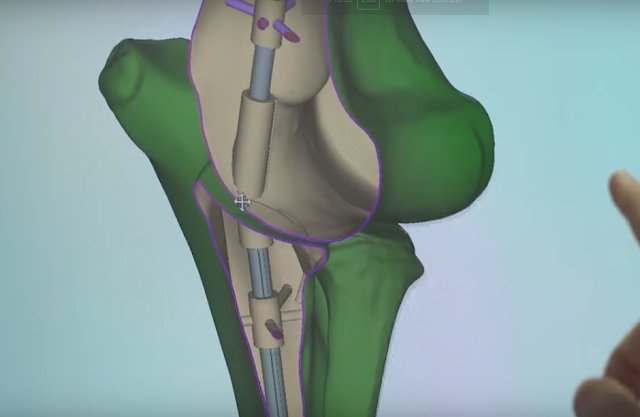

| 3D printing on medical equipment |

I wrote about the 3D printing market forecasts, standards, assessment, modern technology as well as materials that could flourish and also increase in 2019. This short article will concentrate on companies that are making it take place: How Stratasys is promoting carbon fiber tooling, Ford as well as Carbon's deal with the F-150 Raptor Auxiliary Plugs, Ultimaker's expanded press right into industrial printing, and Optomec obtaining Huffman to accel the business right into the repair service and aftermarket.

Stratasys and also 3D Printed Tooling

Utilizing 3D printing indirectly can be a fantastic means the process can increase production. Often individuals assume of printing parts, however printing jigs, fixtures, as well as even molds have actually shown a great deal of value in the industrial markets.

Customers can print plastic molds for layup, print a tool straight, or make use of the FDM's dissolvable support materials to streamline the manufacturing of hollow and also trapped-tool arrangements. The tool product liquifies in a detergent remedy, leaving only the healed composite component and also enabling one-piece, smooth layouts. This was shown at JEC World, in Paris Nord - Villepinte, on March 12-14 by Stratasys as it showcased its latest 3D printing improvements for composite manufacturing: high-performance, affordable 3D printed devices.

Designers are seeing exactly how FDM Nylon 12CF can replace standard metal get rid of 3D-printed plastic compounds. This carbon fiber-filled thermoplastic includes 35% cut carbon-fiber as well as with tensile stamina over 9 kips it is solid enough to replace metal. The high stiffness-to-weight proportion of FDM Nylon 12CF is excellent for functional efficiency screening needs in automotive, aerospace, leisure items, as well as industrial manufacturing sectors.

Ultimaker in an Industrial Environment

Ultimaker is frequently classified as a hobbiest printer. Like Stratasys, market are using the printers for tooling, components, and also ergonomics. One instance of desktop computer 3D printing being utilized at scale today can be located at Volkswagen Autoeuropa, a VW plant in Portugal that creates 100,000 automobiles each year and concentrates on design developments as well as new versions.

Making use of a group of desktop 3D printers, the VW production plant created 1,000 tools last in 2016-- consisting of gauges, jigs, as well as components. Printing on-demand in the plant, as opposed to outsourcing, lowered tool development by 95%, and also saved 90% in production costs.

Lately, Ultimaker's profile was selected by Airbus for 3D printing in Europe. The marketplace for 3D printing technology and materials in aerospace is anticipated to increase to $531.1 M by 2024, according to Frost & Sullivan. From manufacturing help and models to end-use parts, desktop computer 3D printers are making it possible for organizations like Airbus and Royal Netherlands Airforce to innovate on the fly while preparing the labor force for tomorrow (no matter technical acumen).

Ultimaker S5

The S5 launched in 2018 provides a larger develop area and other features that show Ultimaker is aiming to relocate right into even more commercial applications.

Airbus will generally use the Ultimaker profile for the direct, neighborhood manufacturing of jigs, tools, and also components, as well as printing lightweight layout components with composite products. But why not a large extra expensive that might use even more functions?

Ultimaker was selected by Airbus as a result of its convenience of usage, dependable results, and open innovation, which fulfills the stringent needs the aerospace market. On top of that, Ultimaker's open resource software application Cura functions so well some competing printer produces use it to run their printer.

According to a current Frost & Sullivan report, the international 3D printing products market for the aerospace market is anticipated to reach $535.1 million by 2024. Plane has actually traditionally welcomed 3D printing, and the partnership with Ultimaker more emphasizes their commitment to more utilizing 3D printing within their manufacturing facilities.

" We are very honored that Airbus chose Ultimaker. Stringent regulations regarding safety and security and also certifications can make manufacturing as well as model-making process made complex, especially for designers in the aerospace sector," states Jos Burger, CEO at Ultimaker.

Ford and Carbon

Recently at the 2019 North American International Auto Show, Carbon unveiled the initial digitally made polymer components in manufacturing for Ford Motor Company. The components consist of Ford Focus HVAC Lever Arm Service Parts, Ford F-150 Raptor Auxiliary Plugs for a specific niche market, and Ford Mustang GT500 Electric Parking Brake Brackets.

The constant liquid interface 3D printing process established by Carbon made headlines when it was released just a few years back. In part one of Manufacturing Trends: 2019 for 3D printing, I stated the digital string.

Ford HVAC lever arm

3D printing let the part number and other details to be printed into the component so you don't have to fret about labels putting on gradually.

On January 16 at the 2019 North American International Auto Show (NAIAS) in Detroit, Carbon revealed the initial digitally produced polymer components in manufacturing for Ford Motor Company. The companies collectively presented the applications at the Additive Manufacturing for Automotive Workshop.

Carbon's durable EPX 82 product confirmed excellent for these components, passing Ford's strenuous performance criteria and also enduring crucial requirements such as indoor weathering; brief- as well as lasting heat exposures; UV security; liquid and chemical resistance; flammability (ISO 3795); and fogging (SAEJ1756) for the selected applications.

" We are delighted to be teaming up with Ford Motor Company and also are thrilled concerning the many opportunities to take advantage of the power of digital manufacturing to supply sturdy, end-use get rid of comparable-- or better-- buildings as injection molded components," stated Dr. Joseph DeSimone, CEO and Co-founder of Carbon. "The automobile industry shows significant pledge for making use of electronic construction at range, and our collaborate with Ford is an ideal example of the sort of technology you can achieve when you design on the methods of production."

Ford parking break bracket

The products industry is continually locating brand-new methods to produce more powerful polymers that can be used in 3D printing. The majority of plastic extrusion models' restriction will certainly be their nozzle temperature level capability. Higher-performing as well as more powerful polymers tend to have higher melting points.

Optomec as well as the Aftermarket

Moving right into even more commercial components, last December Optomec announced that it has gotten Huffman. Huffman's devices and software program remain in manufacturing at basically all significant producers of airplane engines and also commercial gas turbines, who use its metal deposition capabilities to restore damaged or used components at significantly lower price than newly-made extra components.

In 2019 as well as moving forward, it resembles companies will get each other. Consortiums and also partnerships may also see a boost in the number of exist or a boost in membership. Functioning together has actually stimulated development in several industries, such as what the Industrial Internet Consortium (IIC) has provided for the Industrial Internet of Things (IIoT).

In this procurement, both Optomec and also Huffman provide Directed Energy Deposition (DED) solutions. This procedure can be ideal for repair, as feeding cable or blowing powder includes steel to existing components that can be grated or brightened if essential. Furthermore, the DED process works in finish applications that expand the helpful life of components.

"The chance for additive manufacturing in fixing applications is usually forgotten, however when you think about that deterioration as well as use expense the U.S. economy $300 billion annually, and that the international industrial air travel market invests almost $100 billion annually on fixing, you can obtain a better feeling of the magnitude of these markets," claimed Mr. David Ramahi, president and also CEO of Optomec.

These are just a few of the firms locating methods to make use of 3D printing to boost production and also produce bulks. Moving into 2019 the advantages of these very early adopters will be seen extra, and also various other firms will see that comprehending exactly how to use this innovation procedure is essential to remain on the leading side.

Related Articles on 3D printing:

Post a Comment